Our expertise covers a wide spectrum with an emphasis on high wear parts, seed metering assemblies and tractor components, to name a few.

Capabilities

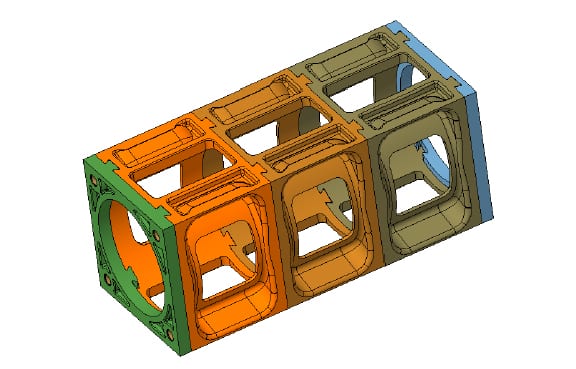

- Metal to plastic conversion

- Multi-year project development & collaboration and Design for Manufacture (DFM) support

- ISO 9001

- CMM measurements and capability studies

- PPAP

- IMDS

- Material silos to purchase in truck load or rail car quantities

- Over molding

- 750T machines for large part requirements

- Stocking of specific automotive materials, many of which are glass filled.

- Secondary operations such as machining, inserting, hot stamping and ultra sonic welding to a name a few

- Mold flow analysis

“We recognize Columbia as one of the top four engineering molders in all of North America.”