How We Can Help

Our advanced capabilities include:

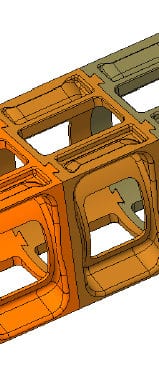

- Moldflow Analysis: Utilizing cutting-edge simulation software, we ensure optimal mold design and manufacturing efficiency, reducing potential defects and enhancing product quality.

- Product Development: From concept to production, our team collaborates closely with clients to bring their ideas to life, offering expert guidance and support throughout the entire development process.

- Injection Molding: Leveraging state-of-the-art technology and equipment, we deliver high-precision injection molding services that meet the most stringent quality standards.

- Assembly of Products: Our comprehensive assembly services streamline the production process, allowing for efficient integration of multiple components into finished products.

- High Volume Manufacturing: With a focus on scalability and efficiency, we excel in high-volume production runs, ensuring consistent quality and timely delivery for large-scale projects.

How We Work

Our Equipment and Technology

At Columbia Plastics, our state-of-the-art 50,000 square foot manufacturing facility in Surrey, BC, is a testament to our commitment to excellence and innovation. Certified with ISO 9001 and 13485 standards and registered with the FDA, our facility operates 24/5, adhering to Lean Manufacturing Principles to ensure efficiency and quality in every production run. We specialize in scientific molding and automation, allowing us to handle both small and large production runs with precision.

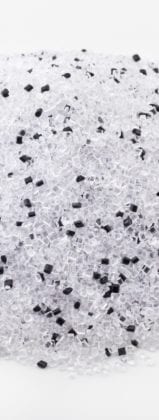

Boasting the largest number of molding machines (17-750 MTon) in Canada west of Ontario, we are equipped to support high-volume production for a diverse range of clients. Our advanced machinery is capable of processing a wide variety of both semi-crystalline and amorphous plastics, ensuring we can meet the specific needs of each project.

Our in-house tool room plays a crucial role in maintaining optimal production flow. By managing mold maintenance and design modifications internally, we ensure minimal tool downtime and maximum efficiency. This capability allows us to swiftly adapt to design changes and maintain the highest standards of quality.

Our management philosophy centers on transparency and teamwork. Through our Continuous Improvement Through Teams (C.I.T.T.) program, we foster a proactive environment that prioritizes safety and consistently meets client expectations. For decades, this approach has driven us to deliver exceptional solutions and maintain a safe, collaborative workplace.