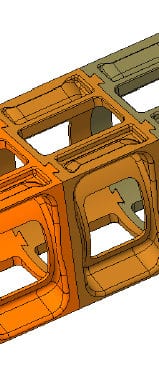

Our Mold Design Process

At Columbia Plastics, our mold design process is a meticulous journey from concept to creation, ensuring your project’s success every step of the way. Here’s how we turn your vision into a high-quality, precision mold:

How We Work

Custom Mold Solutions

At Columbia Plastics, we specialize in creating custom molds tailored to your unique project needs. Whether you require intricate geometries, multi-cavity designs, or specialized features, our team delivers molds that meet the highest standards of precision and performance. From complex prototypes to high-volume production molds, we ensure each solution is designed to enhance your production efficiency and product quality.