How We Work

Our Capabilities

- New product development support and DFM

- Low temperature plastics

- Material silos to purchase in truck load or rail car quantities

- Industry leading UV protection

- Secondary operations and assembly

- Ready for market packaging

- Material silos to purchase in truck load or rail car quantities

- Material analysis

Plastic Fabrication & Forming Solutions

At Columbia Plastics, we offer comprehensive plastic fabrication and forming solutions designed to meet the specific needs of our clients. Our state-of-the-art facility and experienced team enable us to handle a wide variety of projects, from simple components to complex assemblies. We utilize advanced techniques and high-quality materials to ensure that each product meets the highest standards of durability and performance.

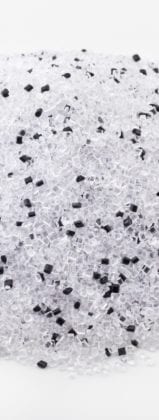

Whether you need prototypes, small production runs, or large-scale manufacturing, we have the capabilities to deliver on time and within budget. We work with a diverse range of plastics, including ABS, acrylic, polycarbonate, and PVC, to create products that are tailored to your exact requirements.

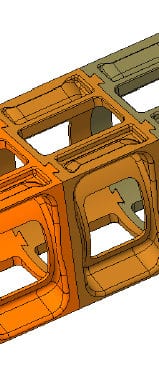

We can create intricate and detailed plastic components with exceptional accuracy. Our forming solutions are ideal for producing everything from custom enclosures and panels to complex geometric shapes, ensuring that your products not only meet but exceed your expectations.

Our Plastic Fabrication Facility

At Columbia Plastics, we proudly serve our diverse global clients from our 50,000 square foot, ISO 9001 and 13485 certified, and FDA registered manufacturing center located in Surrey, BC. Operating 24/5, we adhere to Lean Manufacturing Principles to efficiently manage both small and large production runs, leveraging scientific molding and automation for optimal results.

Our facility houses the largest number of molding machines in Canada west of Ontario, with capabilities ranging from 17 to 750 metric tons. This extensive capacity enables us to support high-volume customers while handling a wide range of both semi-crystalline and amorphous plastics with precision and reliability.

With an in-house tool room, we maintain complete control over mold maintenance and design modifications, ensuring minimal downtime and seamless production processes. Our ability to swiftly address and adapt to tooling needs enhances our efficiency and reliability in delivering top-quality products.

Our management philosophy centers on transparency and teamwork. For decades, we have implemented our Continuous Improvement Through Teams (C.I.T.T.) program, fostering a proactive environment that consistently meets client expectations while prioritizing the safety and well-being of our employees.