How We Work

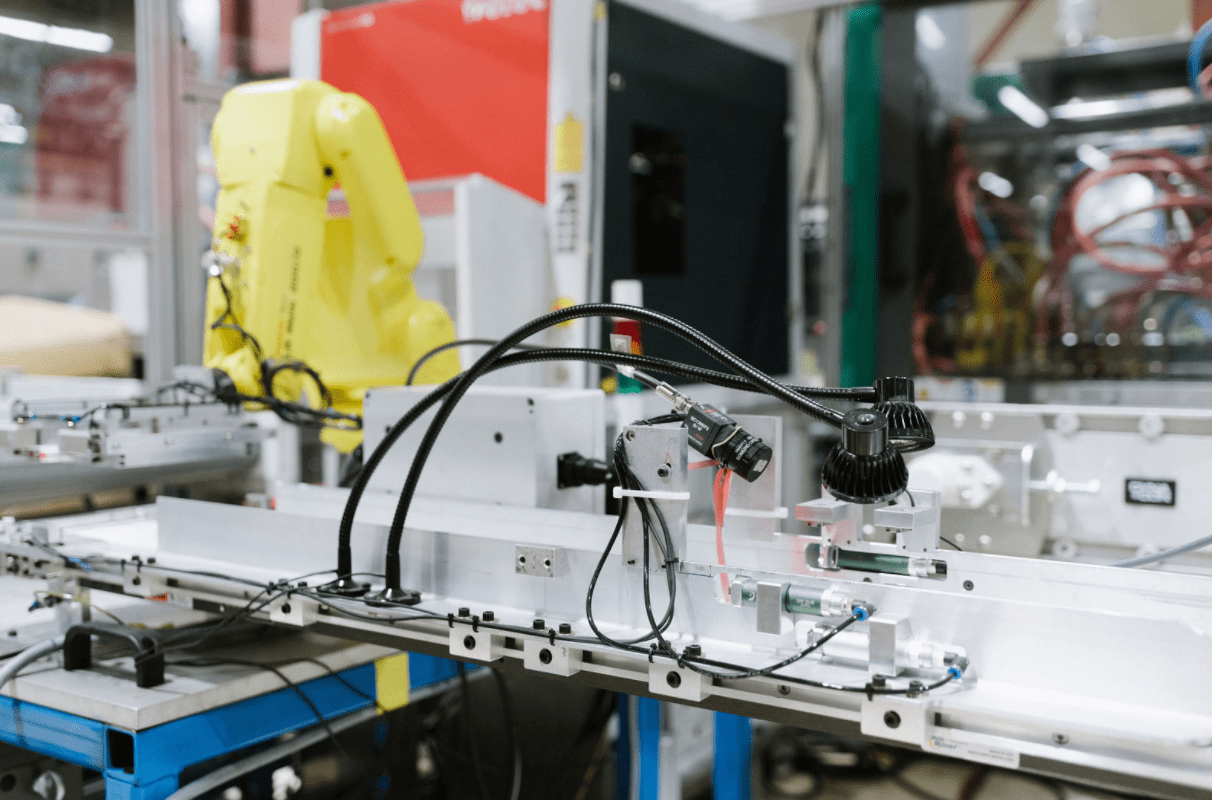

Our Facility

We serve our diverse global clients from our 50,000 square foot ISO 9001, 13485 certified and FDA registered manufacturing centre in Surrey, BC. We operate 24/5 using Lean Manufacturing Principles on small to large production runs while utilizing scientific molding and automation.

We have the largest number of molding machines (17-750 MTon) in Canada west of Ontario supporting our high-volume customers while focusing on a wide range of both semi-crystalline and amorphous plastics.

Our in house tool room allows us to control mold maintenance, complete design modifications and ensure minimal tool down time in production.

Our management philosophy is one of transparency and teamwork. For decades we have utilized our Continuous Improvement Through Teams (C.I.T.T.) program that creates a pro-active environment that ensures our solution meets your expectations and our people stay safe.

Western Canada’s first Class 7 10,000 Cleanroom

Our cleanroom plastic injection molding facilities can be augmented by custom assembly and packaging machinery needed to meet your needs. We also offer in custom in process testing, vacuum formed packaging and Tyvek as well as automatic adhesive deposition. All our medical and clean room molds are designed with in mold sensors for greater process control, automated reject detection and superior IQ/OQ/PQ validation.

Our Projects

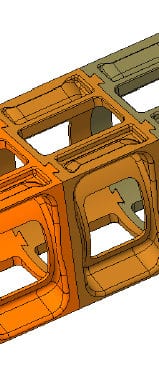

This open atmosphere is what has made us so successful and popular with our clients. We solve problems. We innovate. We make your products better. Not just in the process and manufacture of components, but knowing the parts we make go to making lives better.

Whether it’s a piece of vital medical equipment or a pill vial, we take pride in delivering solutions that make a difference.

View our industry specific case studies below on how we have helped our clients so far.